Insulation Standards Account For Settling

For decades, misinformation has swirled around how much cellulose insulation settles. The “myth” of exaggerating the settling of cellulose insulation was probably initiated in the 1970s by industry competitors and has continued to propagate in online posts and offline articles through the present day. The fact is, some minor settling naturally occurs in all loose fill and even batt insulation products. However, manufacturers for years have been required to provide clear information for their insulation products to account for this minor occurrence.

For decades, misinformation has swirled around how much cellulose insulation settles. The “myth” of exaggerating the settling of cellulose insulation was probably initiated in the 1970s by industry competitors and has continued to propagate in online posts and offline articles through the present day. The fact is, some minor settling naturally occurs in all loose fill and even batt insulation products. However, manufacturers for years have been required to provide clear information for their insulation products to account for this minor occurrence.

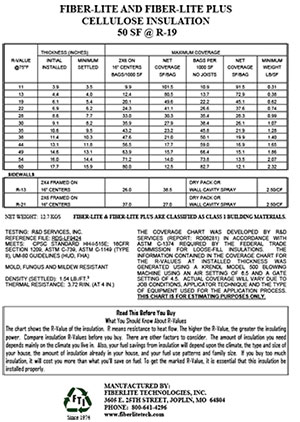

Back in the early 1970s, the entire insulation industry, including fiberglass, was loosely regulated. This changed in the late 1970s and early 1980s when standards were adopted to regulate insulation manufacturers and their products. One measure that was taken required all cellulose insulation manufacturers to include coverage charts on their product bags for “installed” thickness and “settled” thickness. This simple change addressed the concerns with settling providing a factual calculation contractors and consumers could expect to achieve desired R-Value or thickness.

The reason for this modification is that once insulation is blown into an attic, the material will naturally take two to three days to reach its final density. A slight difference in the thickness will occur as the cellulose attic insulation settles into place. As can be seen from the examples provided here, the change in depth is minimal. For example in an attic insulated to R49 (R-Value) the cellulose insulation material will settle about an inch and half. Industry, as well as internal Fiberlite research, suggests this occurs within the first 48-72 hours after the material is installed into an attic.

The reason for this modification is that once insulation is blown into an attic, the material will naturally take two to three days to reach its final density. A slight difference in the thickness will occur as the cellulose attic insulation settles into place. As can be seen from the examples provided here, the change in depth is minimal. For example in an attic insulated to R49 (R-Value) the cellulose insulation material will settle about an inch and half. Industry, as well as internal Fiberlite research, suggests this occurs within the first 48-72 hours after the material is installed into an attic.

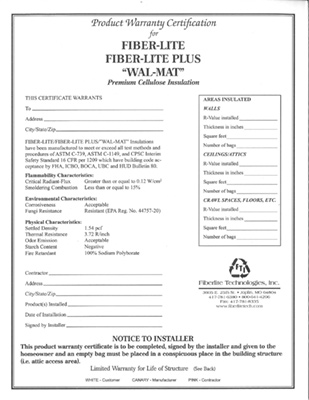

Since FTI started manufacturing cellulose insulation in1985, this standard has always been in place and coverage charts printed prominently on all product bags sold. When installed properly to the indicated depth on the bags, consumers can rest assured the final R-Value will be achieved providing high energy efficiency and savings for the life of the dwelling.

Many homeowners make the mistake of adding plywood decking over the joists in home attics to create a convenient storage floor for all the stuff they can’t fit in their garages. This is a bad idea since the most cost effective way to insulate an attic is to cover the floor with insulation. If the floor is covered in plywood at the typical joist tops it’s just not possible, in most cases, to stuff enough insulation underneath to obtain the required depth and R-Value.

Many homeowners make the mistake of adding plywood decking over the joists in home attics to create a convenient storage floor for all the stuff they can’t fit in their garages. This is a bad idea since the most cost effective way to insulate an attic is to cover the floor with insulation. If the floor is covered in plywood at the typical joist tops it’s just not possible, in most cases, to stuff enough insulation underneath to obtain the required depth and R-Value. Ant infestations are one of the most common pest problems in homes and businesses creating an irritating nuisance and a source of disgust, concern and frustration for occupants. Ants are considered one of the most difficult pests to control, along with bed bugs. There are a staggering number of ants on the planet with a

Ant infestations are one of the most common pest problems in homes and businesses creating an irritating nuisance and a source of disgust, concern and frustration for occupants. Ants are considered one of the most difficult pests to control, along with bed bugs. There are a staggering number of ants on the planet with a  Myths have been perpetuated about cellulose insulation for years. While most of this misinformation has centered around fire, moisture and settling topics, a new category has emerged recently: PEX.

Myths have been perpetuated about cellulose insulation for years. While most of this misinformation has centered around fire, moisture and settling topics, a new category has emerged recently: PEX. Surprisingly,

Surprisingly,  By Shan Maitra, Fiberlite Technologies President

By Shan Maitra, Fiberlite Technologies President

Homeowners and Insulation Industry Professionals new to FTI Products may not be aware of the difference between Fiber-Lite and Fiber-Lite Plus. Overall, these two products are very similar. They have comparable R-Values, product densities, and meet similar

Homeowners and Insulation Industry Professionals new to FTI Products may not be aware of the difference between Fiber-Lite and Fiber-Lite Plus. Overall, these two products are very similar. They have comparable R-Values, product densities, and meet similar

Customers often ask the team here at Fiberlite “which cellulose product is best for my insulation project?” With many brands and types of cellulose insulation on the market, it can be confusing to homeowners and even some builders and other industry professionals when choosing a product.

Customers often ask the team here at Fiberlite “which cellulose product is best for my insulation project?” With many brands and types of cellulose insulation on the market, it can be confusing to homeowners and even some builders and other industry professionals when choosing a product.