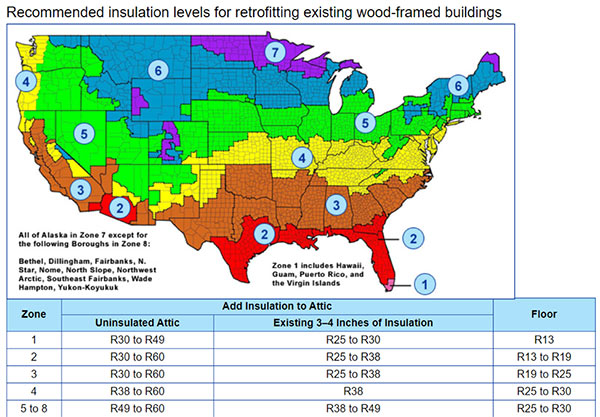

DOE Map Provides Recommended Insulation Levels

The Department of Energy (DOE) has created a detailed map for recommended R-Values throughout the United States. This map reflects their research on the different climate zones and number of heating and cooling days. If the only consideration is energy efficiency, more is always better. However, the DOE map suggests the appropriate insulation level, which is cost-effective. An uninsulated attic has a wide range between R30-R60. Below is the DOE map for the Continental US, which is divided into seven (7) climate zones. The Midwest is generally covered in climate zones 3,4 and 5.

FTI’s family of Attic Plus products is the perfect product to meet the DOE’s recommendation. Generally, insulation contractors install Attic Plus Pro. Also, many home and hardware stores stock Attic Plus for Do It Yourself (DIY) project installations. They are similarly formulated and meet all ASTM standards for insulation. Learn more about what R-Value really means.

Contact Fiberlite with questions or to inquire about installing Attic Plus products.

Once the area is prepped, the contractor drills holes into the wall between each wall cavity. An application hose is inserted through these holes and insulation is blown under pressure, dense packing the product into the cavity. When the contractor cannot add more insulation, they raise the hose a foot at a time and blow more insulation. This process is repeated until the entire cavity is filled. Once completed, the holes are patched and if on the exterior any siding material is reattached.

Once the area is prepped, the contractor drills holes into the wall between each wall cavity. An application hose is inserted through these holes and insulation is blown under pressure, dense packing the product into the cavity. When the contractor cannot add more insulation, they raise the hose a foot at a time and blow more insulation. This process is repeated until the entire cavity is filled. Once completed, the holes are patched and if on the exterior any siding material is reattached.

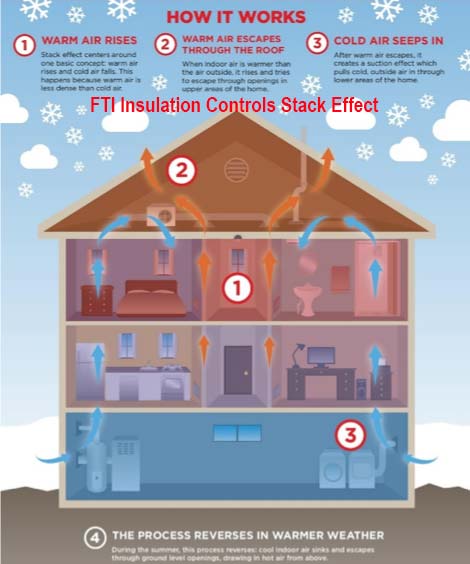

Research has shown that approximately 30% to 50% of energy used for heating and cooling is lost due to air leakage. One of the primary driving forces for air leakage loss is a phenomenon where air flows within and through the building called stack effect.

Research has shown that approximately 30% to 50% of energy used for heating and cooling is lost due to air leakage. One of the primary driving forces for air leakage loss is a phenomenon where air flows within and through the building called stack effect.

What else happened in 1974? Fiberlite Technologies, Inc (FTI) was formed by P.K. Maitra. Originally called P.K. Insulation (PKI), this business catered to the industrial market and started with only one client. PKI manufactured thermal insulating cements for application to heated equipment for the power and process industries. In 1985, FTI acquired the assets for a small home insulation manufacturing company and began producing cellulose insulation.

What else happened in 1974? Fiberlite Technologies, Inc (FTI) was formed by P.K. Maitra. Originally called P.K. Insulation (PKI), this business catered to the industrial market and started with only one client. PKI manufactured thermal insulating cements for application to heated equipment for the power and process industries. In 1985, FTI acquired the assets for a small home insulation manufacturing company and began producing cellulose insulation. Cathedral ceiling construction is more susceptible to moisture damage than open attic construction. The construction of a cathedral ceiling creates air spaces in rafter cavities. Filling the cathedral ceiling with FIBER-LITE Cellulose Insulation is a very effective way to block the air movement.

Cathedral ceiling construction is more susceptible to moisture damage than open attic construction. The construction of a cathedral ceiling creates air spaces in rafter cavities. Filling the cathedral ceiling with FIBER-LITE Cellulose Insulation is a very effective way to block the air movement.